Hard to leave Cape Town on a perfect winter morning like this!

Fortunately the trip back to SALT included a few highlights along the way... An impressive collection of classic cars assembled in Matjiesfontein while we were stopped there for lunch.

Then an encounter with a magnificent Martial Eagle on the road between Matjiesfontein & Sutherland :)

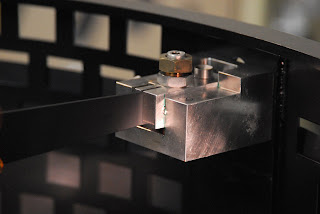

Up in the clean room, we got back to trying to measure the reflectivity of M5 while M4's out of the way. A laser's mounted so as to point down through the hole in the super-structure platform & a calibrated diode (connected to a picoammeter) is attached to the side of the laser to pick up the reflected beam.

To calibrate the M5 measurements we use a small reflectivity standard mounted on a bar that fits across the top of the SAC. The bar's slid into position so that the laser beam hits the reference mirror & the return's steered back up to the diode by adjusting the mirror in tip & tilt.

In principle it works, but we don't believe the results as individual sets of M5 & reference mirror measurements are practically identical & the 2 mirror surfaces are Not. So unfortunately this experiment doesn't seem possible with our current setup...

Meanwhile, next door in the spectrometer room, (amongst many other things) the RSS team's been testing the Fabry-Perot etalons before they can be re-integrated into the instrument.

The fluorescent tube in the light table produces mercury emission lines which the etalons convert into a series of rings.