Darragh's blasted through the M4-M5 alignment process during the past few days! X & Y scans (as described in the November 29 post) to sort out the M4 decentre...

& the image-distance vs object-distance scans (described in the December 8 post) to get the axial spacing of the pair right. Squares indicating the actual measurements are shown along with the theoretical curves in the plot below. Note the excellent agreement between the large red squares & the central dark blue curve that corresponds to the effective focal length of the pair in the nominal optical prescription of the telescope.

After a set of M4 Faro measurements, it was time to remove & replace the steering wheel to check the repeatability of the M4 mount.

While M4 was out of the way, we Faro'd M5 & the pinhole again & confirmed that they're still where they should be. Then put M4 back, Faro'd it again & found the repeatability to be extremely good - of order 10 microns in decentre & about 35 microns in despace!

At this stage we were ready to test the pair at angle. A wavefront RMS of 0.036 waves was obtained with the SAC vertical.

Then it was tilted over to 37 degrees, M4 Faro'd & wavefronts measured.

Only tiny changes in the pinhole position (indicating mirror movements of about 10 microns, in agreement with the Faro readings) were needed to get back to a RMS of 0.038 waves :) We obtained equally good results for the SAC at the other extremes of its operational envelope (tipped over to + & - 6 degrees in X & from 31 to 43 degrees in Y).

Lastly, it was time to cycle the temperature in the clean room - down to about 11 C & back up to 23 C, making wavefront measurements with the SAC vertical & tilted to 43 degrees at various intervals during the temperature change. This all looks great too!

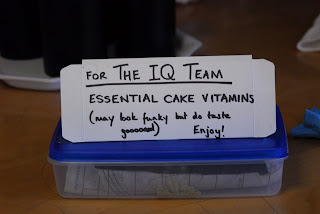

So the pair's happy at angle & over a range in temperature! With that - we're out of here, for nearly a month :) The team members will attempt to unwind & possibly even re-establish some semblance of their pre-clean room lives... Enjoy the Holidays everyone!