A few members of the team spent this week working in Cape Town as the Faro testing that needed to be done could easily be carried out in the lab at the SAAO. With the arm set up on its test plate & all the accessories scattered around like our favourite toys, it felt just like home...

We wanted to test our extension probes to see if any are capable of delivering the sort of accuracy we'll need for the remaining steps in the repair plan. The short, standard Faro probe (left in the pic below) defined our best case & then we set about putting the different custom-made probes through their paces. These included a hollow stainless steel probe (seen here after it'd been tested & had its nose transplanted to its solid stainless steel cousin), as well as hollow & solid carbon fibre probes that underwent various surgeries of their own.

Although the probes were given unfairly harsh physicals - the sets of Single Point Accuracy Tests (SPATs) involved the largest amplitude movements possible in all directions - the results were rather disappointing in most cases...

Happily though, the solid stainless steel probe performed brilliantly - almost matching the SPAT results for the short probe & so we have a winner :)

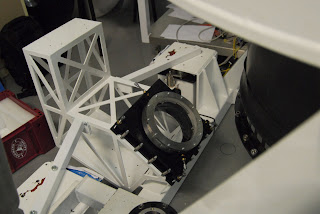

We also had a chance to check out the titanium base that'll hold the new CGH - seen here (upside-down) sporting its zippy flexures.

& we got Malcolm to aluminise a spot on the curved surface of null lens for us. This was necessary as we have to be able to pick up that surface with the 94%-reflective reference mirror on the interferometer (as that's what the M2 test will be done with), but the uncoated lens only produces useful fringes if we use the 4%-reflective reference mirror. This cunning work-around's perfect as the central part of the null lens falls within the central obscuration due to the hole in M2 & thus doesn't participate in the M2 test.